Products

Our Products

Trust the Innovation

Instacrete Dry Concrete Mix

Dry Packaged Concrete Mix produced in Kenya. High quality processed materials including machine washed and sieved river sand. Mix is class 25 where factory batching ensures accuracy.

More Details

Concrete is the second most consumed item in the world. The only other item that is consumed more is water.

Dry mix Portland cement concrete, often referred to as dry mix concrete or dry batch concrete, is a versatile construction material that offers several advantages over traditional wet mix concrete. This innovative approach to concrete mixing involves pre-mixing the dry ingredients, including Portland cement, aggregates, and additives, before water is added on-site.

One of the primary benefits of dry mix concrete is its ease of transportation and storage. By blending the components in a controlled environment and delivering them to the construction site as a dry mixture, the need for large, cumbersome concrete mixing trucks is minimized. This reduces logistical challenges and allows for efficient distribution to remote or challenging-to-access locations.

Another advantage is the improved quality control that dry mix concrete offers. Precise measurements of the individual ingredients ensure consistent mix ratios, leading to uniformity in strength and durability across batches. This predictability in performance is particularly crucial for any kind of projects, both small and large.

Construction timelines can be expedited through the use of dry mix concrete. The absence of setting time constraints associated with traditional wet concrete allows for greater flexibility during pouring, placing, and finishing. This can lead to increased productivity and faster project completion, saving both time and money.

In Kenya and most of the emerging economies, the manual mixing of stockpiled materials always lead to

• Material losses

• Material wastage

• Poor quality control

• Unnecessary labor overheads

• Poor estimation of quantities leading to unused stockpiled materials

With Instacrete Dry Concrete Mix, all those challenges are eliminated.

Instacrete Dry Concrete Mix is produced by blending high quality RIVER SAND, high Strength quality cement from Bamburi Cement and Mombasa cement and quality approved aggregates from Quarries in Mavoko, Nairobi. We use an aggregate grading with size ranging from 3mm to 15mm size particles. Our sand meets the grading profile set by the regulating bodies.

The components are batched by weight using a well calibrated batching plant and mixing is done in batches that ensure optimal mixing. Our mixing plant mixes the components through 16 different motions and vibration ensuring the matrix produced is even, have consistency and minimal segregation.

With Instacrete Concrete Mix, you will never go wrong. With more than enough cement constituent, you will not need to come back to smoothen your surface.

Try it today for any kind of construction work.

Ongeza Maji Tu!

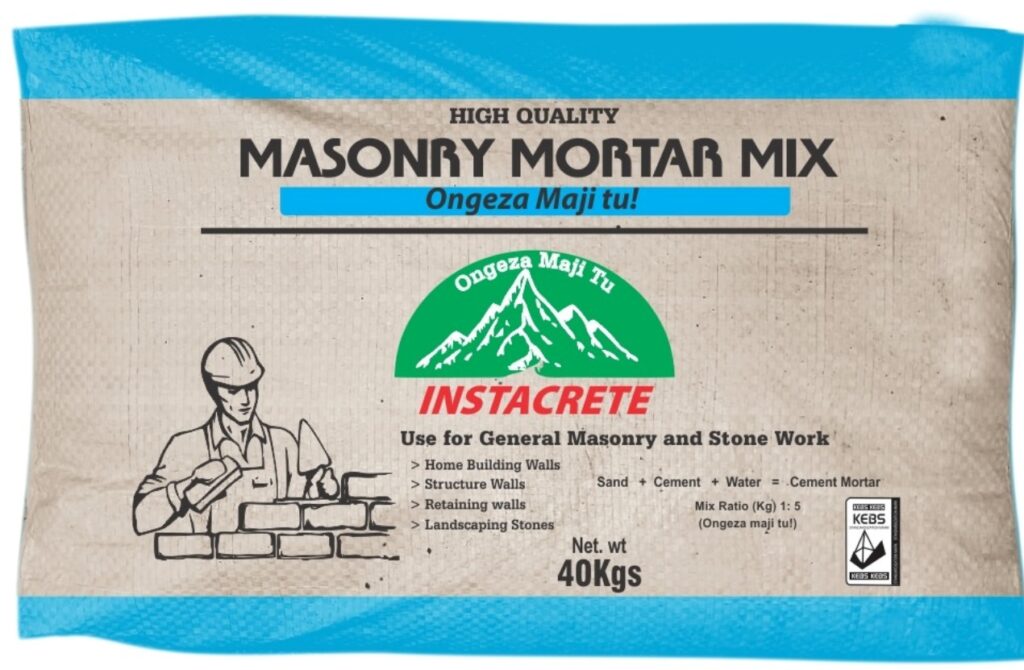

Instacrete Masonry Mortar Mix

High quality and durable mix for easy masonry work. Convenient quantities in bags ensures easy handling and transportation. No more overheads due to stockpiling needs.

More Details

For most home and property builders, once masonry stones are procured and delivered, sand and cement will need to be delivered in a given bulk quantities and stockpiled.

This has several impacts;

1.Sand stockpiled is susceptible to contamination, loss due to erosion and general loss of quality

2.Cement bags delivered to site are highly susceptible to loss through stealing and thievery

3.A minimum amount of money not less than Ksh. 100,000 will have to be accumulated for the first single building stone to be laid.

Not anymore!

With Instacrete Dry Mortar Mix, you can start your sub and super structure wall construction the day the first stone is delivered!

Instacrete dry mortar mix is mix of blended RIVER SAND and high-quality cement mixed at a rich ration of 1kilogram of cement to 5kilogram of sand by highly accurate batching equipment.

The mix is packaged in bags of 40kg, that can lay up to 40 ft of building masonry stones.

This means that once you have procured your building stones, you can start laying them on immediately. All you will need to do is determine the number of feet your Fundi can lay in a day and order your bags based on assuming 40ft per bag.

This ensures that,

1. No more need to stock pile

2. Less labour as you will not need labour to process(sieve), transport and mix sand.

3. No need for space to stockpile

4. No losses and inaccurate delivery of sand

5. Quick, clean and organized construction process.

6. Many more benefits

Try today our mortar mix and experience the convenience.

Ongeza Maji Tu!

Instacrete Dry Plaster Mix (Stucco)

One 40Kg bag of Plaster Mix can cover up to 40 square feet of wall with 9mm thick film of plaster. No need for waiting to stock pile. No need to wait to accumulate sand after the building is completed.

Instacrete Products Inquiry?

Leave your contact

We will call you back